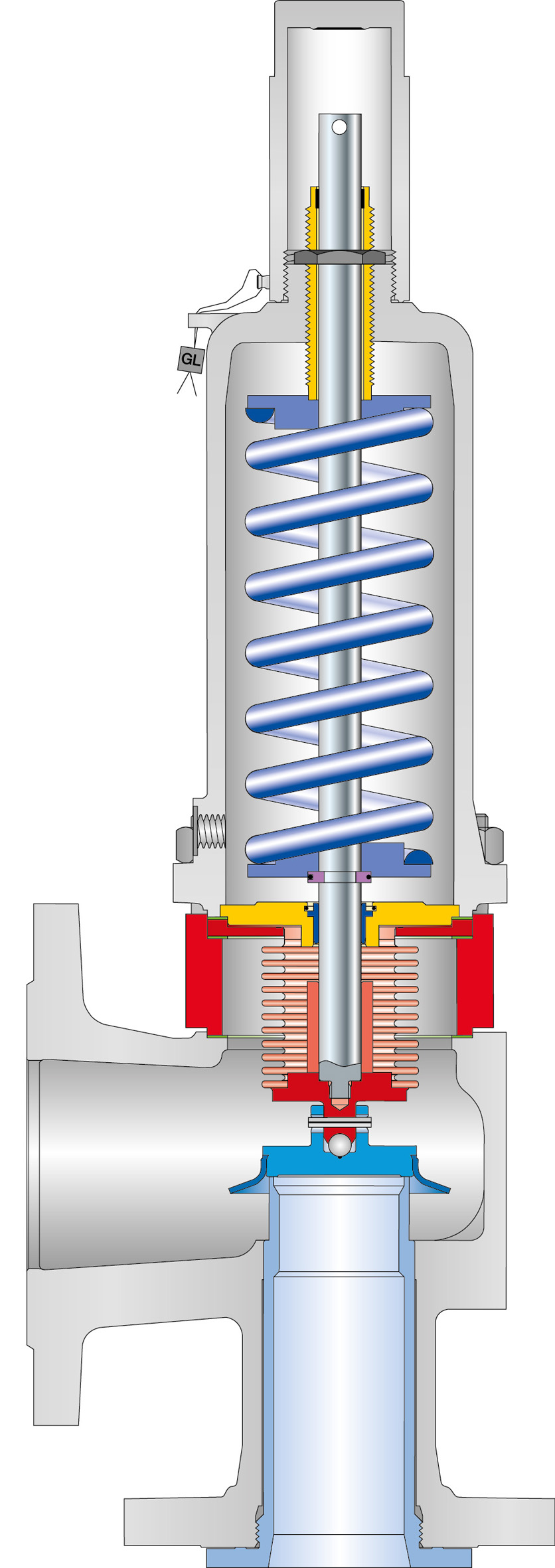

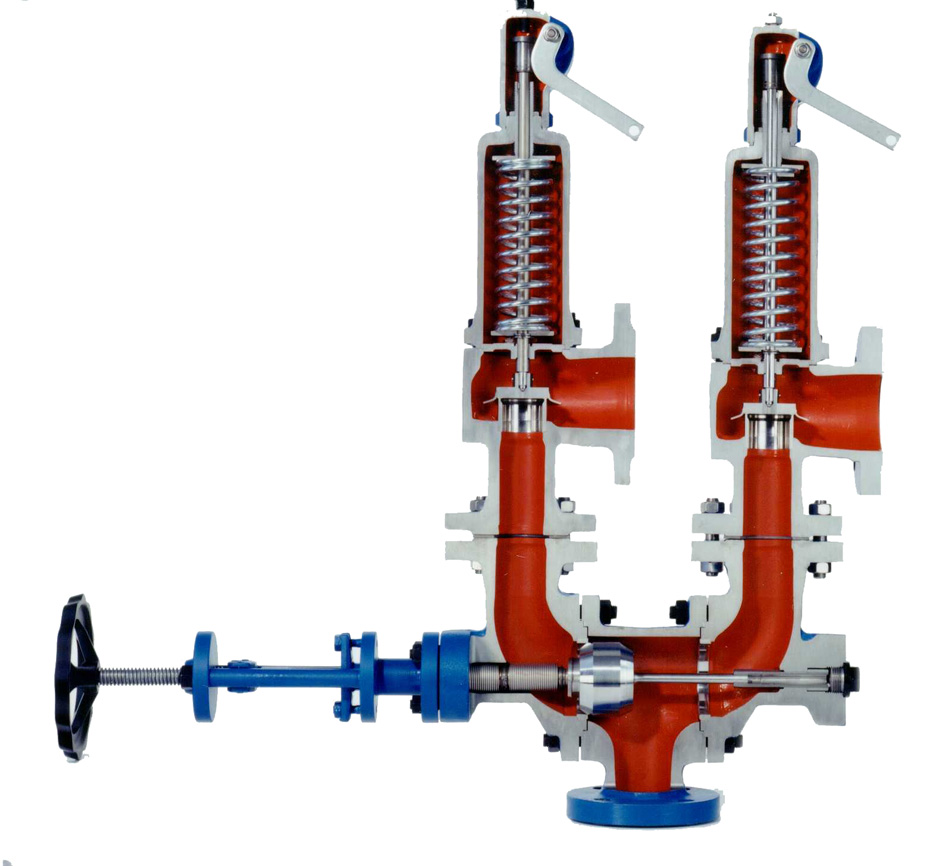

With more than 800 employees, LESER is the largest manufacturer of safety valves in Europe and a leader in its market worldwide. LESER safety valves are used by leading companies in industries such as chemical, petrochemical, industrial gases, oil and gas production, and machine building, as well as the food and pharmaceutical industry.

LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements.

LESER safety valves are developed for the international market at our headquarters in Hamburg / Germany and manufactured at our modern factory in Hohenwestedt / Germany.

LESER S&R safety valve

LESER S&R safety valve LESER Urea safety valve

LESER Urea safety valve LESER High Efficiency safety valve

LESER High Efficiency safety valve LESER Change-over Valve

LESER Change-over Valve LESER Critical service 447

LESER Critical service 447 LESER Modulate Action safety valve

LESER Modulate Action safety valve LESER Clean Service safety valve

LESER Clean Service safety valve LESER High Perfomance safety vlave

LESER High Perfomance safety vlave

Schutte & Koerting has more than a century of experience in the design and manufacture of steam jet vacuum systems, steam jet heaters, exhausters and compressors, scrubber systems, desuperheaters, thermocompressors, eductors and syphons, ejectors, and valves. S&K maintains an experienced staff of design and test engineers to solve the most challenging vacuum process requirements. The company’s ability to design both standard product and custom equipment has been the basis for its longevity and success.

Our customers benefit from the staff of Engineers, Administrators, Managers, and the extensive network of sales and service offices located around the world. We serve the Chemical, Petroleum, Petrochemical, Food, Pulp and Paper, Power, Metal Refining, Water and Waste Treatment Industries, among others.

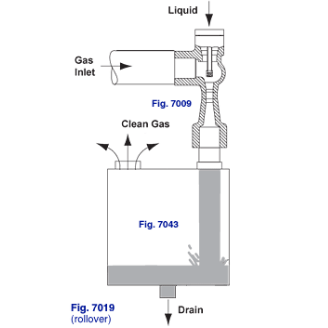

S&K Ejector Venturi Gas Scrubber

S&K Ejector Venturi Gas Scrubber S&K Vent Gas Scrubber System

S&K Vent Gas Scrubber System S&K Packaged Scrubber System

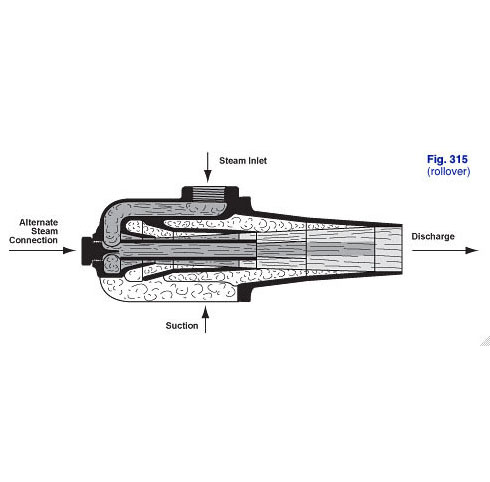

S&K Packaged Scrubber System S&K Single-Stage Steam Jet Ejector

S&K Single-Stage Steam Jet Ejector S&K Multi-Stage Steam Jet Ejectors

S&K Multi-Stage Steam Jet Ejectors S&K Gas Jet Compresser

S&K Gas Jet Compresser S&K Circulating Heaters

S&K Circulating Heaters S&K Sparger Nozzles

S&K Sparger Nozzles

The independent family enterprise, founded in 1973, employs a global workforce of around 250. REMBE® has its headquarters in Brilon, in the hills of the Sauerland region (Germany), and runs 9 subsidiaries to support its worldwide customers right where they are. Thanks to its short lines of communication, the company can respond quickly and find customised solutions for all applications, ranging from standard products to special high-tech designs.REMBE® provides customers in all industries with safety systems for their plants and equipment.

REMBE Explosion Venting Q-Box

REMBE Explosion Venting Q-Box REMBE HPRD-5000barg series

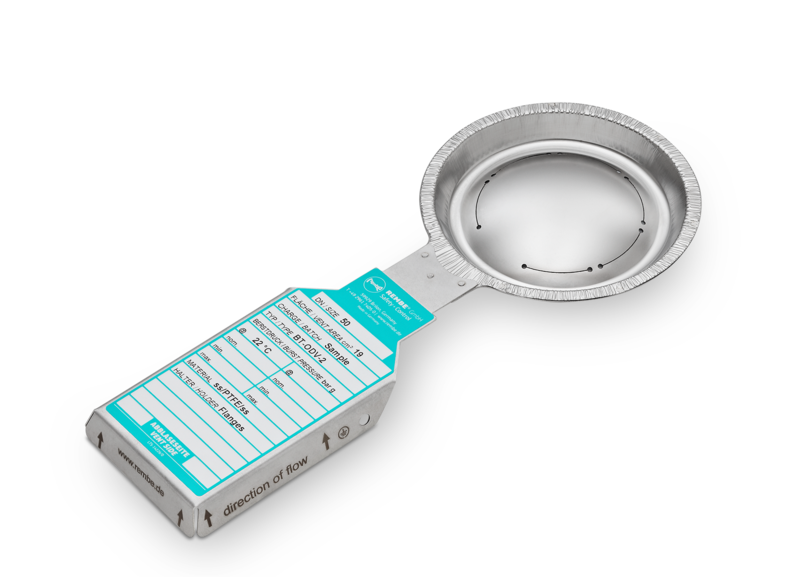

REMBE HPRD-5000barg series REMBE Forward acting rupture disc ODV series

REMBE Forward acting rupture disc ODV series REMBE Reverse acting rupture disc IKB series

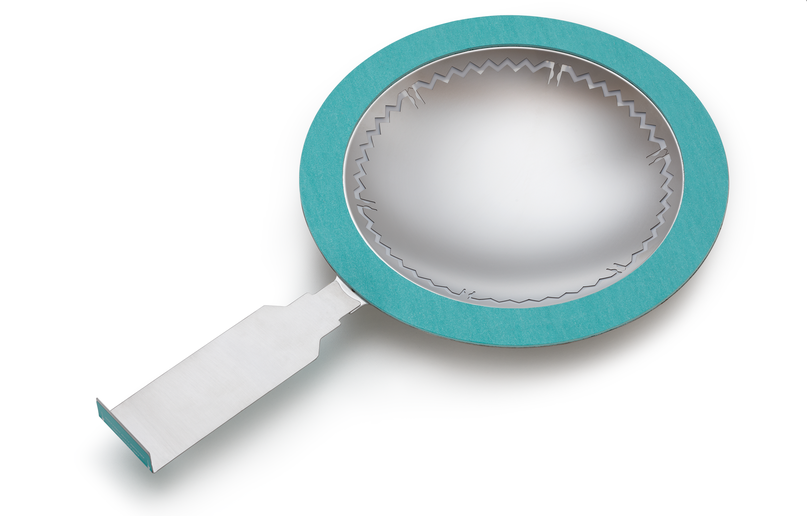

REMBE Reverse acting rupture disc IKB series REMBE KUB Clean series

REMBE KUB Clean series REMBE Reverse acting rupture disc KUB series

REMBE Reverse acting rupture disc KUB series REMBE Explosion Venting EDP

REMBE Explosion Venting EDP REMBE Forward acting rupture disc CBS series

REMBE Forward acting rupture disc CBS series

Today, with about 70 employees, KITO® manufactures flame arresters, valves and special devices for a diverse array of customer requirements. Just like top-ranking athletes, we are never satisfied with average performance levels. Our aim is to produce innovative and efficient solutions for explosion prevention & protection, with a consistent focus on quality, protection and safety.

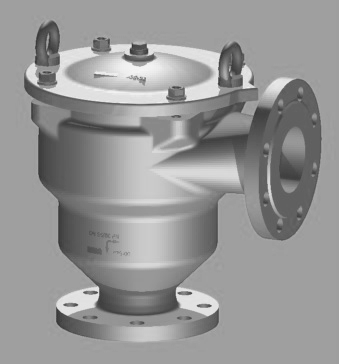

KITO Pressure and vacuum relief valve

KITO Pressure and vacuum relief valve KITO Deflagration proof pressure and vacuum relief valve

KITO Deflagration proof pressure and vacuum relief valve KITO Uni-directional end-of-line liquid detonation flame arrester

KITO Uni-directional end-of-line liquid detonation flame arrester KITO Pressure and vacuum relief valve Products advantages As end-of-line armature, for venting aper

KITO Pressure and vacuum relief valve Products advantages As end-of-line armature, for venting aper KITO Bi-directional in-line detonation flame arrester

KITO Bi-directional in-line detonation flame arrester KITO Uni-directional in-line detonation flame arrester

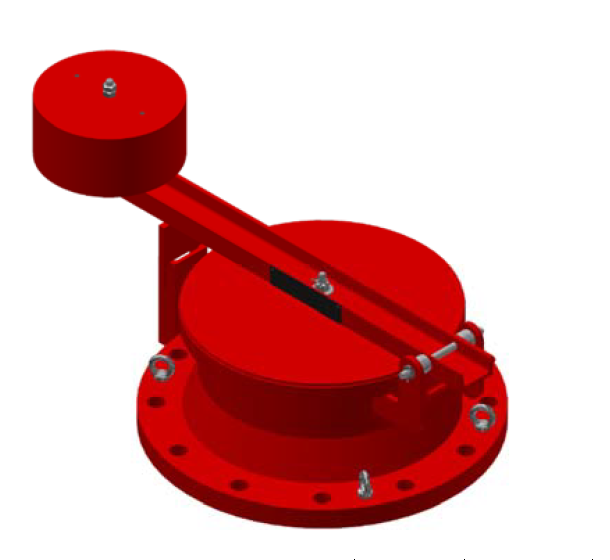

KITO Uni-directional in-line detonation flame arrester KITO Emergency Pressure relief valve

KITO Emergency Pressure relief valve

As a Dutch company established in 1966, we have been an international leader in our field for many years. We develop and produce a wide range of high quality butterfly valves and accessories. Our main goal is to provide our customers with solutions that fit both their needs and their budgets. In order to achieve this we take great efforts to know the different worlds in which our customers operate. Manufacturers of butterfly valves can be found all over the world. However, manufacturers with five decades’ worth of experience and know-how are few and far between. Wouter Witzel is one of them. Ever since 1966 we have been internationally renowned for industrial butterfly valves and actuators. Our constant monitoring of market developments allows us to always respond quickly to new demands. In close consultation with our customers we translate state of the art technology into innovative solutions. These match both the desired application and all other requirements.

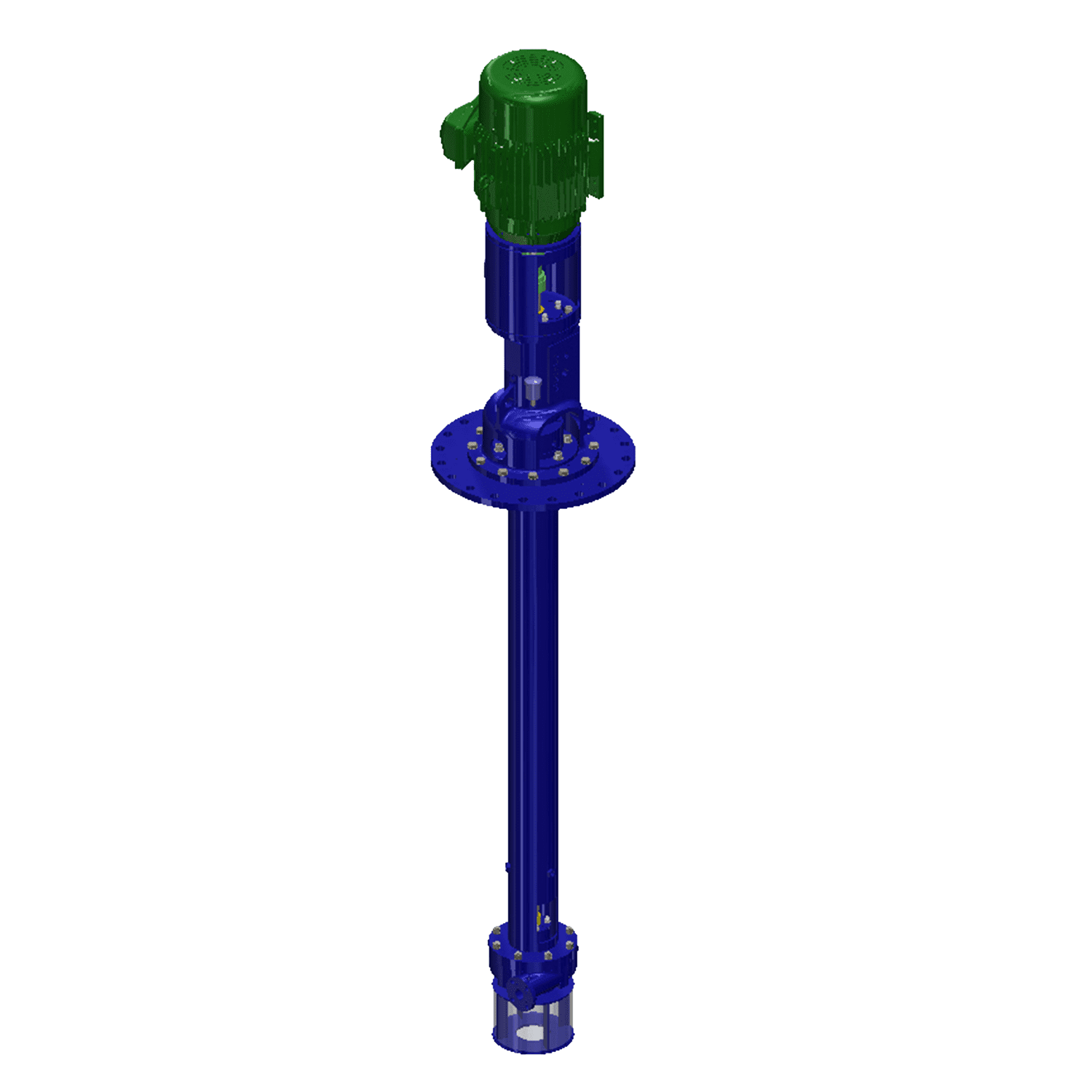

Discflo Corporation is an innovative pump manufacturing company, specializing in pumps for the toughest industrial applications. We have built a reputation over 20 years for solving pumping problems in a wide range of industries, from the onshore and offshore oil market to chemical processing, from municipal wastewater treatment to food and pharmaceutical manufacture, and paper production.

We are best known for our innovative Disc Pump technology, a unique ‘non-impingement’ method of pumping using the patented Discpac impeller. Disc Pumps have proven very successful in slashing operating costs, prolonging pump life and preventing damage to emulsions and delicate product.

INNOMAG has strongly focused on vertical integration and vertical manufacturing for one reason and one reason only, QUALITY! High quality is the result of good raw materials, making things yourself and having employees who care about what they make! Why is INNOMAG so different? Our answer is simple… constant involvement! It’s not just the concept of Thrust Balancing or that each engineer has over two decades of sealless engineering experience but rather everyone’s relentless desire to stay involved with every facet of the business. While many of our competitors have stagnated over the years, we're constantly improving our products and our production methods to insure the best quality pump possible