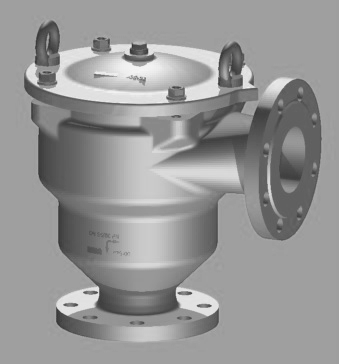

KITO Uni-directional in-line detonation flame arrester

|

Products advantages For installation into pipes to protect containers and components against stable detonation of flammable liquids and gases. Tested and approved as detonation flame arrester type 4. Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Working unidirectional in pipes, whereby an operating pressure of 1.2 bar abs. and an maximum operating temperature of 60 °C must not be exceeded. Provided with one temperature sensor (PT 100) the armature is certified against short time burning from one side. The installation is not dependent on the position and both directions of flow are possible. During installation,please observe the direction of detonation and the indication protected side. |

||||||||||||||

|

Technical specifications |

|

|||||||||||||

|

Housing / valve seat edge |

cast steel 1.0619, cast steel 1.4408 |

|||||||||||||

|

Max. working Pressure |

1.2 barg |

|||||||||||||

|

Max. working Temperature |

60 °C |

|||||||||||||

|

MESG |

MESG> 0.9 mm. |

|||||||||||||

|

Nominal Diameter |

DN 25 - DN 100 | 1" - 4" |

|||||||||||||

|

Temperature sensor |

Optionally£¨PT 100, connection 3/8“, 1.4571£© |

|||||||||||||

|

Flange connection |

EN 1092-1 Typ type B1, ASME B16.5 Class 150 RF, API standard 650 (optionally) |

|||||||||||||

|

Industries

|

|

|||||||||||||

|

||||||||||||||