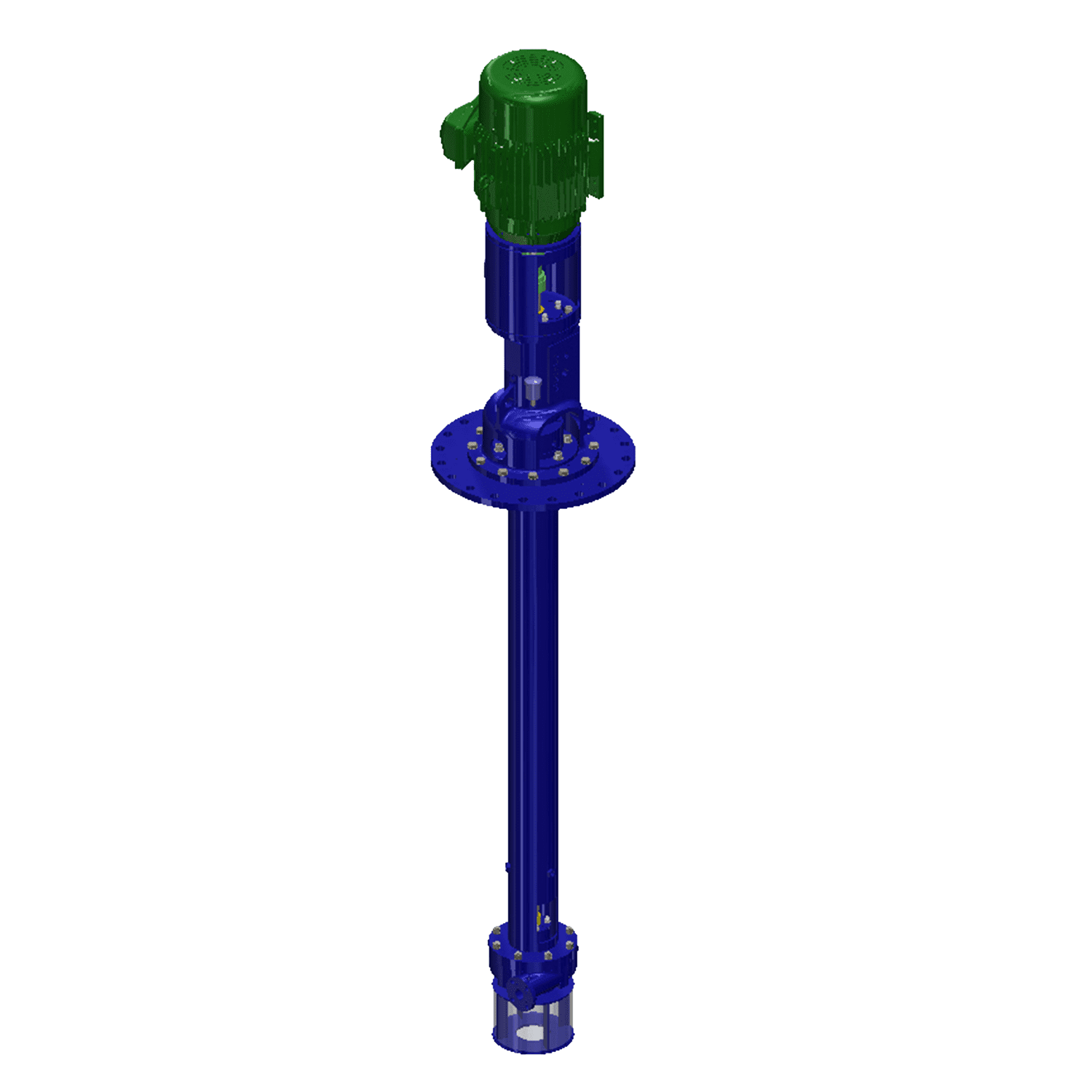

Disc Mixers

|

Products advantages The Discmixer mixes using parallel discs, either smooth or ribbed, which rotate perpendicular to the shaft. During mixing, a boundary layer is formed on the disc surfaces as they rotate. This layer protects the mixer from wear.

|

|

|

n Our record of success in the highly competitive pump market is a result of breakthrough, state of the art pump technology and a commitment to provide the most efficiency and economical solutions to the toughest pumping problems. |

|

|

n No radial Loads-The Disc pump uses a new and patented technology that isn’t available in any other pump. The technology of the Disc pump harnesses the natural power of boundary layer and viscous drag. |

|

|

n No impingement-Boundary layer-a boundary layer of fluid molecules collects, and rotates with discs. This creates a natural, protective buffer that separates the pump from fluids, |

|

|

n No Pulsating-Viscous Drag n Little maintenance required n Few spare partsLittle or No downtime |

|

|

Applications |

|

|

n Viscous and high solid fluids. |

|

|

n Abrasive fluids-lime sludge, Bio-solids sludge, Sand slurries with up to 80% solids, sewage. |

|

|

n Air or gas-entrained fluids |

|